Project Name: INA Bearings

System Provided: ELV Systems (ACS, BMS-SCADA, CCTV, DATA, PA, WLD, Rodent Repellant)

Client Name: DEVI Constructions Co. Pvt. Ltd.

Location: Talegaon Floriculture Park, Pune

Client Introduction

DEVI Group has a legacy of over 60 years in building construction with operation ranging from, as Government contractors to Private Industrial and Residential design and developments. The Group’s diverse portfolio, with management’s hands on experience and personnel expertise’s have successfully delivered simple to complex industrial structures, affordable to luxury housing, small society’s to large townships, making DEVI a favorite amongst Architects, Consultants and Customers alike.

Project Introduction

DEVI Constructions (DCCPL) bagged the Turnkey project from INA Bearings. This project was an extension to the existing plant of INA Bearings. Devi’s scope included entire Civil, HVAC, Electrical, Fire Fighting, Solar and ELV works. For ELV works they were looking for a single agency having capability to handle all ELV Systems i.e. ACS, BMS, CCTV, DATA Networking, PA etc. After multiple technical and commercial discussions, Techbean received the job for the entire ELV package.

The main objective was to equip whole extended plant and office building with the ELV systems i.e. Access Control System, BMS-SCADA, CCTV, DATA Networking and Public Address System.

DATA networking and CCTV systems comprised of about 5kms CAT-7 cabling and 1.8kms of Fiber optic cabling. The PA system captured the entire plant with 3kms cabling and about 100speakers.

The Access control, Water Leak Detection and Rodent Repellant were not that big as other systems but efficiently completed in important rooms viz. Server, BMS, Battery, UPS and Entrance lobbies.

In the end due to excellent on site coordination by Techbean with appropriate support from Devi, consultant and end client, the project was completed in time with minimum snags. This project will be registered as one of the landmark projects for Techbean.

The project was challenging due to many factors such as critical deadline, dependency on multiple agencies, continuous co-ordination DEVI team & consultant, change management due to site conditions and end client requirements and also the spread of the plant.

DATA networking and CCTV systems comprised of about 5kms CAT-7 cabling and 1.8kms of Fiber optic cabling. The PA system captured the entire plant with 3kms cabling and about 100 speakers.

The Access control, Water Leak Detection and Rodent Repellant were not that big as other systems but efficiently completed in important rooms viz. Server, BMS, Battery, UPS and Entrance lobbies.

In the end due to excellent on site coordination by Techbean with appropriate support from Devi, consultant and end client, the project was completed in time with minimum snags. This project will be registered as one of the landmark projects for Techbean.

Client requirement

System-wise requirements from the client were as follows;

- SCADA BMS: Energy management and consumption calculation was the main focus of It was required to monitor and control all the plumbing and electrical systems located in the facility from a single platform. They also required a high-tech system where commanding the systems, history logs and alarm notifications can be made available from any PC in their network.

- DATA Networking: For office area client wanted to cover all the PCs, Wi-Fi devices, projectors and other machines. While for the Plant production area all the points were provided on the tray so as they can tap it from the machine head, Wi-Fi points in the plant production area.

- CCTV: Covering the periphery of the plant, Office entrance and Office building 1st floor (BMS, Server, UPS rooms), apart from that Video Fire Detection cameras in the production area., apart from that Video Fire Detection cameras in the production area.

- PA: Announcements, alerts should be audible in office area as well production area. Production areas being noisy horn type speakers were required. Announcements to be made from central location.

- ACS: Entrance lobbies, Server room, BMS room, UPS room were required to access controlled

- Water Leak Detection and Rodent Repellant: These systems were required for the server and BMS room.

Product Details

SCADA BMS:

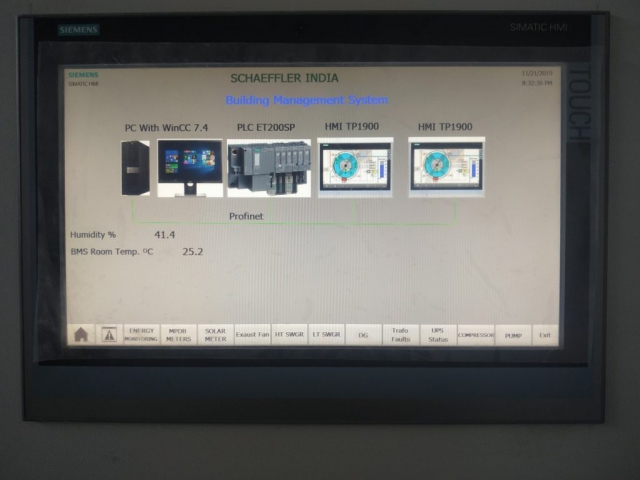

- Siemens latest series SIMATIC ET200SP PLC along with Master-Slave MODBUS cards, Cards for digital and analog points, RTD modules for integration of different types of points on a single PLC.

- 19″ Model-1900 Comfort HMIs for BMS operator to easily monitor and operate alarms, notifications of the system of which graphics are designed so as they can be easily operated from HMIs.

- WIN-CC V7.4- Standard SCADA Software for history/trends and logs to be saved on the workstation in graphical and tabular formats. Time Scheduling can be assigned and overridden when required from the software.

- Attractive, customized and live graphical display on HMIs for ease of operation and understanding of customer

CCTV and DATA Networking:

- Overall Data Networking and CCTV system cabling (CAT 7 and OFC both) were of standard Legrand make. Data networking racks, patch panels, IOs etc. all were of Legrand make in totality.

- Up to 150mtrs of coverage for Axis PTZ cameras with the pan, tilt and zoom function for overall monitoring as per requirement.

- Axis fixed 2MP Dome cameras for office area surveillance. Up to 32channels NVR with Axis Client software for easy monitoring and operation.

- Bosch Video Fire detection 8MP Bullet cameras for Fire alert and video surveillance both.

PA System:

- Bosch PAVIRO digital controller for up to 10 zones connectivity and zone-wise as per requirement programming was used.

- 6W ceiling mount, box wall mount speakers of office area & entrance lobbies and 30W Horn type speakers for production area along with Call station for operator.

- ACS and Time attendance:

- 2 door 4 readers controller, Mifare R10 i-class readers, HID cards, Biometric Time attendance device were used which can store up to 55000 transactions.

- Enterprise Attendance Management Software for over 2000 employees to monitor daily attendance.

WLD and Rodent Repellant:

- A 4 zone Water leak detection system with Buzzer for entire server room periphery coverage for any case of water leak in the room.

- Rodent controller with up to 20 transducer satellites for entire server room coverage from rodents.

SCADA BMS Details OF INA BEARING

Following systems available at INA Bearing which were integrated to BMS:

- Pump room- Fire Pump, Jockey Pump, Water Pump, 3 tanks level sensors.

- Compressors, UPS, DG Set, MPDBs, Main DB energy meters, Solar meter, Lighting DB DALI controller, Humidity sensors on MODBUS

- HT Board, Transformers, Incomer Breaker contacts, RTDs as Hardpoints.

Handover process

In Handover process of ELV Systems, all the systems were one by one is demonstrated for monitoring/control and operation respectively. All agreed features on SCADA BMS were tested in the presence of site in charge. Subsequently the engineering and services team were trained for all features of various systems This training session is basically a practical hands-on session of ELV systems with maximum interaction from client side.

A handover document is submitted to the customer, it includes the detailed logic description of all systems, system architecture and layout, SLD, operation & maintenance manual, supplier & service centre details and Escalation list of service team.